The radio frequency spectrum extends from DC (0hz) to about 3thz (3,000,000,000,000 hz). Anything above that becomes light. The microwave spectrum is anything above 300 mhz. There are numerous types of modulation. Modulation is accomplished by varying one factor of the given wave. (ie frequency, amplitude, etc) Thus the names frequency modulation (FM) and amplitude modulation (AM). Ham radio operators are restricted to certain frequencies and types of modulation. It's possible to create a relay (repeater) system with any frequency and modulation type. You could create one that operated in the FM and band but worked on amplitude modulation. Technically it's against the law but so is what the government is doing.

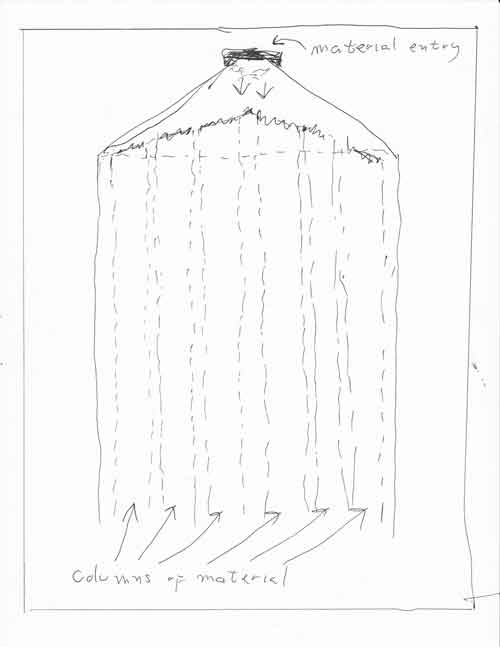

At some point in the future it might be useful to jam everything but one band of frequency's. (see picture below) Design a noise generator that produces noise over the entire frequency spectrum then filter it for a specific band and put the noise through a mixer circuit along with the data.

The radio frequency spectrum extends from DC (0hz) to about 3thz (3,000,000,000,000 hz). Anything above that becomes light. The microwave spectrum is anything above 300 mhz. There are numerous types of modulation. Modulation is accomplished by varying one factor of the given wave. (ie frequency, amplitude, etc) Thus the names frequency modulation (FM) and amplitude modulation (AM). Ham radio operators are restricted to certain frequencies and types of modulation. It's possible to create a relay (repeater) system with any frequency and modulation type. You could create one that operated in the FM and band but worked on amplitude modulation. Technically it's against the law but so is what the government is doing.

At some point in the future it might be useful to jam everything but one band of frequency's. (see picture below) Design a noise generator that produces noise over the entire frequency spectrum then filter it for a specific band and put the noise through a mixer circuit along with the data.

Addendum. Today I watched a couple videos about people designing alternative DNS systems. I don’t think this is totally necessary. At least not in small towns. DNS stands for Domain Name Service, or Server ??,. It is a way to route a communication. It’s like an operator in the early days of telephone. Operators sat at a board and physically made the connection to route a call from one place to another. Today it’s done automatically with computers. DNS is the internet equivalent. Lets say you had a small town of about 50,000 people. Everyone’s communications are wireless and handled on one frequency in the microwave range. Everything else was jammed with noise. If someone’s call bounced around the entire town looking for the right end point it wouldn’t take much time and you wouldn’t really notice anything. The frequency is so fast. This is a roundabout example. Anything above 10 hz is not visible to the naked eye. If you pulsed an LED you would see it like it is on all the time once you get it above 10 hz. Any LED monitor or TV has 1000’s of LED that are pulsed many times per second. But it appears to be on all the time. The same effect could be used with voice communications and maybe the internet. Eventually someone might come up with a method to avoid this and save bandwidth and still have no central facility.

Antenna Weave

Did you ever see a picture of the geodesic domes in a NSA spy facility? I think those are antennas. This is what I think is the principle behind their design. Electromagnetic radiation is directional. It depends on how the transmitting antenna is oriented. The electric component is 90 degrees to the magnetic component. (I think) Some Am and FM radios will have an antenna that can be adjusted to maximize the signal. This is why it's adjustable. The geodesic dome allows for the antenna to pick up any radiation in all directions without being adjusted. The geodesic dome was invented by Buckminster Fuller. FYI.

I think it's possible to make a home brew antenna to do the same thing. Get a very long piece of magnet wire. Magnet wire is used in transformers and is designed to pass EMR. (this part I'm not sure is possible) Using one piece of wire weave a mat like a piece of cloth. Stretch the mat into a globe shape. When you're done you will have a very long piece of wire oriented to pick up EMR from any direction. As a rule the longer the antenna the more sensitive it is. A suggestion for the globe would be a beach ball from any dept store. Cover it with plaster of paris and create a sturdy base from wood or metal.

Addendum. Today I watched a couple videos about people designing alternative DNS systems. I don’t think this is totally necessary. At least not in small towns. DNS stands for Domain Name Service, or Server ??,. It is a way to route a communication. It’s like an operator in the early days of telephone. Operators sat at a board and physically made the connection to route a call from one place to another. Today it’s done automatically with computers. DNS is the internet equivalent. Lets say you had a small town of about 50,000 people. Everyone’s communications are wireless and handled on one frequency in the microwave range. Everything else was jammed with noise. If someone’s call bounced around the entire town looking for the right end point it wouldn’t take much time and you wouldn’t really notice anything. The frequency is so fast. This is a roundabout example. Anything above 10 hz is not visible to the naked eye. If you pulsed an LED you would see it like it is on all the time once you get it above 10 hz. Any LED monitor or TV has 1000’s of LED that are pulsed many times per second. But it appears to be on all the time. The same effect could be used with voice communications and maybe the internet. Eventually someone might come up with a method to avoid this and save bandwidth and still have no central facility.

Antenna Weave

Did you ever see a picture of the geodesic domes in a NSA spy facility? I think those are antennas. This is what I think is the principle behind their design. Electromagnetic radiation is directional. It depends on how the transmitting antenna is oriented. The electric component is 90 degrees to the magnetic component. (I think) Some Am and FM radios will have an antenna that can be adjusted to maximize the signal. This is why it's adjustable. The geodesic dome allows for the antenna to pick up any radiation in all directions without being adjusted. The geodesic dome was invented by Buckminster Fuller. FYI.

I think it's possible to make a home brew antenna to do the same thing. Get a very long piece of magnet wire. Magnet wire is used in transformers and is designed to pass EMR. (this part I'm not sure is possible) Using one piece of wire weave a mat like a piece of cloth. Stretch the mat into a globe shape. When you're done you will have a very long piece of wire oriented to pick up EMR from any direction. As a rule the longer the antenna the more sensitive it is. A suggestion for the globe would be a beach ball from any dept store. Cover it with plaster of paris and create a sturdy base from wood or metal.

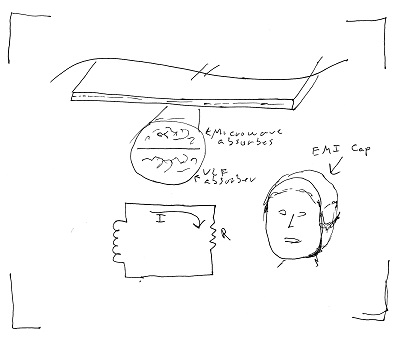

EMI Absorbent

Neural implants probably operate on microwaves given the small size. The same with RFID chips. Satellites and mind controlled people are useless if you can't communicate with them. This is the basic premise behind noise generators. If you wanted to help someone you would have to stop the implant or chip from communicating, get them to a facility that is fully protected from surveillance and they might have to stay there a while. EMI shielding could help cut off communication. A tin foil hat will not work because without a connection to earth ground there is no path for current to flow. No Faraday cage will work without a connection to earth ground. Only the reflectivity properties of whatever metal is used will apply. Reflectivity is only a fraction of what the hat encounters. They make EMI absorbent material. It can be bought from any electronic supply house. Mouser.com and Digikey.com for example. 3M makes a wide variety. A 12 inch by 12 inch piece can run about $50. A person could be covered from head to toe with this and brought to a facility that is a Faraday cage. If you don't cover the face, ground based microwave towers could still access the chip. A Faraday cage is an entire building, or enclosure, encased in copper or aluminum and grounded to earth.

EMI Absorbent

Neural implants probably operate on microwaves given the small size. The same with RFID chips. Satellites and mind controlled people are useless if you can't communicate with them. This is the basic premise behind noise generators. If you wanted to help someone you would have to stop the implant or chip from communicating, get them to a facility that is fully protected from surveillance and they might have to stay there a while. EMI shielding could help cut off communication. A tin foil hat will not work because without a connection to earth ground there is no path for current to flow. No Faraday cage will work without a connection to earth ground. Only the reflectivity properties of whatever metal is used will apply. Reflectivity is only a fraction of what the hat encounters. They make EMI absorbent material. It can be bought from any electronic supply house. Mouser.com and Digikey.com for example. 3M makes a wide variety. A 12 inch by 12 inch piece can run about $50. A person could be covered from head to toe with this and brought to a facility that is a Faraday cage. If you don't cover the face, ground based microwave towers could still access the chip. A Faraday cage is an entire building, or enclosure, encased in copper or aluminum and grounded to earth.

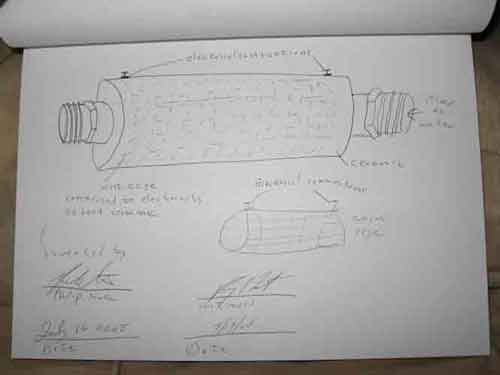

I don't know how EMI absorbent material works. This is 3 ideas of my own. Since the material won't have a connection to ground for current my ideas try to generate current within the material itself. The first idea (top picture) would involve spinning microscopic wires into a material that has a small resistance to current flow. The wires would still have a small amount of insulation on them. They would be spun into small coils. The ends of the coils would be bare so as to make contact with the resistive material and make thousands of microscopic circuits as shown in the drawing. Each circuit would develop current and absorb the EMI.

I don't know how EMI absorbent material works. This is 3 ideas of my own. Since the material won't have a connection to ground for current my ideas try to generate current within the material itself. The first idea (top picture) would involve spinning microscopic wires into a material that has a small resistance to current flow. The wires would still have a small amount of insulation on them. They would be spun into small coils. The ends of the coils would be bare so as to make contact with the resistive material and make thousands of microscopic circuits as shown in the drawing. Each circuit would develop current and absorb the EMI.

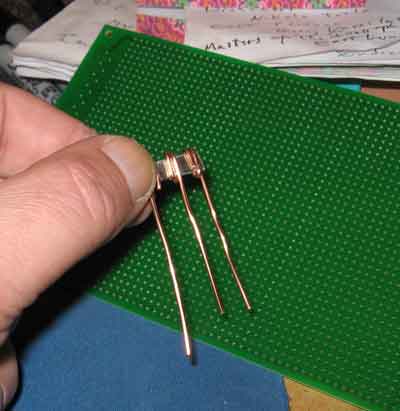

A home brew version might be possible if you bend ordinary 1/4 or 1/8 watt resistors as shown in the next picture and then lay them out on some sort of substrate.

A home brew version might be possible if you bend ordinary 1/4 or 1/8 watt resistors as shown in the next picture and then lay them out on some sort of substrate.

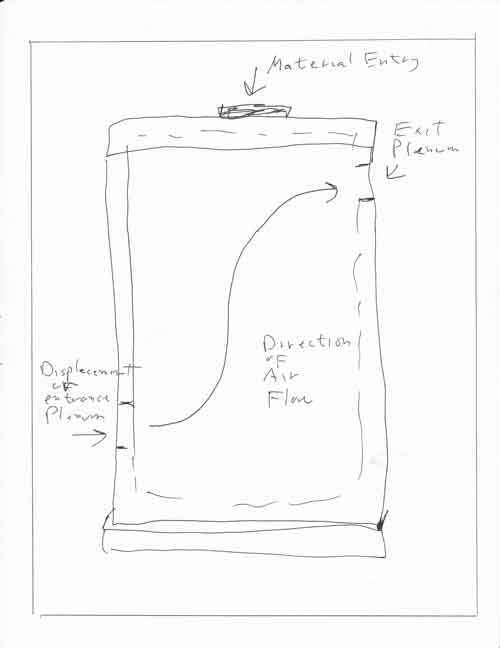

A more complicated version could be made by weaving wires together. It might require building some kind of manufacturing equipment or maybe an ordinary loom could be used. I think you could look up patents in the patent office online on how screen for windows and doors is made and copy that. The idea is to make screen that is half nylon and half aluminum. All the nylon would go one way, either horizontal or vertical, and the aluminum the other way. Every 6 inches or so connect a resistor across 2 of the aluminum strands. Keep each pair of aluminum strands separate from each other. The patent office could be used for all kinds of ways to fight back.

A more complicated version could be made by weaving wires together. It might require building some kind of manufacturing equipment or maybe an ordinary loom could be used. I think you could look up patents in the patent office online on how screen for windows and doors is made and copy that. The idea is to make screen that is half nylon and half aluminum. All the nylon would go one way, either horizontal or vertical, and the aluminum the other way. Every 6 inches or so connect a resistor across 2 of the aluminum strands. Keep each pair of aluminum strands separate from each other. The patent office could be used for all kinds of ways to fight back.

This is an addendum to the EMI absorbent material idea. Along with the mat of woven circuits put a layer of aluminum foil on each side. Aluminum has the best reflective properties of any metal. This will help trap EMI inside the mat. It will also reduce the power that needs to be consumed by reflecting a portion before it gets to the circuits. In addition to the coils and resistors in the circuits you could add an IC that helps to jam whatever is being absorbed. It works the same as an RFID. It's powered by the EMI.

This is an addendum to the EMI absorbent material idea. Along with the mat of woven circuits put a layer of aluminum foil on each side. Aluminum has the best reflective properties of any metal. This will help trap EMI inside the mat. It will also reduce the power that needs to be consumed by reflecting a portion before it gets to the circuits. In addition to the coils and resistors in the circuits you could add an IC that helps to jam whatever is being absorbed. It works the same as an RFID. It's powered by the EMI.

Faraday Cage

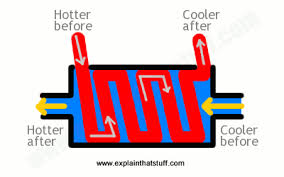

A Faraday cage is an enclosure, room or entire building (like the NSA building at Ft Meade), encased in metal and then grounded to earth. It prevents electromagnetic waves from entering or leaving. It works the same as a coax cable (see picture) If the braided shielding is grounded to earth the conducting core is protected from noise coming from the outside. The NSA building is copper, but aluminum has the best reflective property’s of any metal. Aluminum flashing can be bought at any construction supply (Home Depot, Lowes). Attach it to one side of some plywood panels and place the panels on the floor of the attic. Somehow ground it to earth. There are companies that sell and install metal roofs. This might defeat satellite surveillance but not cell phone towers. If a satellite can pick up EMI at 10,000 miles cell phone towers can do the same. Cell phone systems are on the ground and would be capable of snooping through the walls not the roof. To defeat this, the whole house would have to covered with aluminum. They used to sell aluminum siding, I don’t know if they still do.

Faraday Cage

A Faraday cage is an enclosure, room or entire building (like the NSA building at Ft Meade), encased in metal and then grounded to earth. It prevents electromagnetic waves from entering or leaving. It works the same as a coax cable (see picture) If the braided shielding is grounded to earth the conducting core is protected from noise coming from the outside. The NSA building is copper, but aluminum has the best reflective property’s of any metal. Aluminum flashing can be bought at any construction supply (Home Depot, Lowes). Attach it to one side of some plywood panels and place the panels on the floor of the attic. Somehow ground it to earth. There are companies that sell and install metal roofs. This might defeat satellite surveillance but not cell phone towers. If a satellite can pick up EMI at 10,000 miles cell phone towers can do the same. Cell phone systems are on the ground and would be capable of snooping through the walls not the roof. To defeat this, the whole house would have to covered with aluminum. They used to sell aluminum siding, I don’t know if they still do.

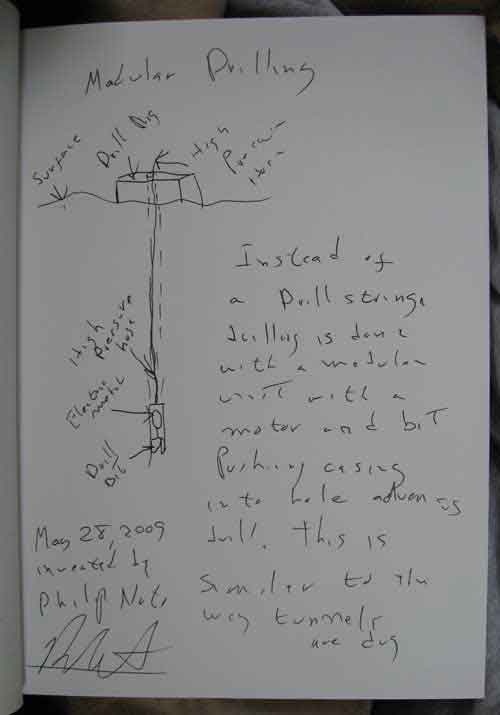

A Faraday cage can protect from radiated intrusion, both transmitted and received, but it doesn’t help with conducted surveillance. Any wire entering or leaving a building and connected to a utility (electric, cable, phone) is a highway for someone to snoop. Any house has thousands of feet of wire. A large building has miles and it can all be used for transferring data. Broadband Over Powerlines (BPL) is a technology that uses the AC wiring in a building for delivering the same data as the coax cable. Telephone wiring could also be used without a person’s knowledge. It used to be that when a device was off it was off. But now almost everything plugged in is drawing current even when not in use. I used to think this was done just to pad the electric bill but it may also have a more sinister purpose. Anything plugged into a wall outlet in your house could be snooping. The wiring itself could be a problem. As a rule the bigger the antenna, the more sensitive it is. So the wiring in your house could be a very sensitive antenna capable of picking up your personal emissions. There are at least 2 ways to defeat some of these problems. Filtering and injecting noise onto the wires.

Some basic filtering solutions are snap on beads and inline filters. (see below) A snap on bead is a ferrite that can be placed on any wire to suppress high speed signals. Inline filters can be bought at home improvement stores and can be placed in series to filter out unwanted frequencies. The third picture is a filter that can be added to home built electronics.

A Faraday cage can protect from radiated intrusion, both transmitted and received, but it doesn’t help with conducted surveillance. Any wire entering or leaving a building and connected to a utility (electric, cable, phone) is a highway for someone to snoop. Any house has thousands of feet of wire. A large building has miles and it can all be used for transferring data. Broadband Over Powerlines (BPL) is a technology that uses the AC wiring in a building for delivering the same data as the coax cable. Telephone wiring could also be used without a person’s knowledge. It used to be that when a device was off it was off. But now almost everything plugged in is drawing current even when not in use. I used to think this was done just to pad the electric bill but it may also have a more sinister purpose. Anything plugged into a wall outlet in your house could be snooping. The wiring itself could be a problem. As a rule the bigger the antenna, the more sensitive it is. So the wiring in your house could be a very sensitive antenna capable of picking up your personal emissions. There are at least 2 ways to defeat some of these problems. Filtering and injecting noise onto the wires.

Some basic filtering solutions are snap on beads and inline filters. (see below) A snap on bead is a ferrite that can be placed on any wire to suppress high speed signals. Inline filters can be bought at home improvement stores and can be placed in series to filter out unwanted frequencies. The third picture is a filter that can be added to home built electronics.

Injecting noise onto AC wiring is basically the same concept as Broadband Over Powerlines. (BOP). It is possible to get a higher frequency signal to 'ride' on a lower frequency signal. X10 technology was invented in the 1980's. X10 uses AC wiring to control lights and other devices inside a home. The same technology could be used to put noise on the AC wiring.

Injecting noise onto AC wiring is basically the same concept as Broadband Over Powerlines. (BOP). It is possible to get a higher frequency signal to 'ride' on a lower frequency signal. X10 technology was invented in the 1980's. X10 uses AC wiring to control lights and other devices inside a home. The same technology could be used to put noise on the AC wiring.

To prevent the AC wiring from picking up your emissions like an antenna you could place all the wiring in conduit or Romex conduit and ground it to earth. I know this makes no sense if your house has already been built but I'm just making a point. It's the same thing as coax cable. The conduit acts like a Faraday Cage and keeps noise from leaving the AC wiring or anything getting onto the wiring. Injecting noise onto the wiring is an alternative if you can't rewire everything. They make shielded AC wire but it's expensive.

To prevent the AC wiring from picking up your emissions like an antenna you could place all the wiring in conduit or Romex conduit and ground it to earth. I know this makes no sense if your house has already been built but I'm just making a point. It's the same thing as coax cable. The conduit acts like a Faraday Cage and keeps noise from leaving the AC wiring or anything getting onto the wiring. Injecting noise onto the wiring is an alternative if you can't rewire everything. They make shielded AC wire but it's expensive.

I think it makes sense to both inject noise onto the wiring and filter it at the same time. Any device plugged in could be conducting surveillance. It could be using the AC wiring to communicate with the outside world. Generating noise inside the house could stop the device from picking anything up and injecting it onto the AC wiring can defeat it's transfer to the outside. Filtering at the same time can make sure.

Sidenote. Some people believe the HAARP facility in Alaska is used in mind control and surveillance. It's stated mission is communicating with submarines on Extremely Low Frequencies. (0 HZ to 100 HZ) In fact they think it operates around 30 HZ. It is possible to get high speed data to 'ride' on the 30 HZ. The 30 HZ might be powering the RFID chips and carrying the communication data.

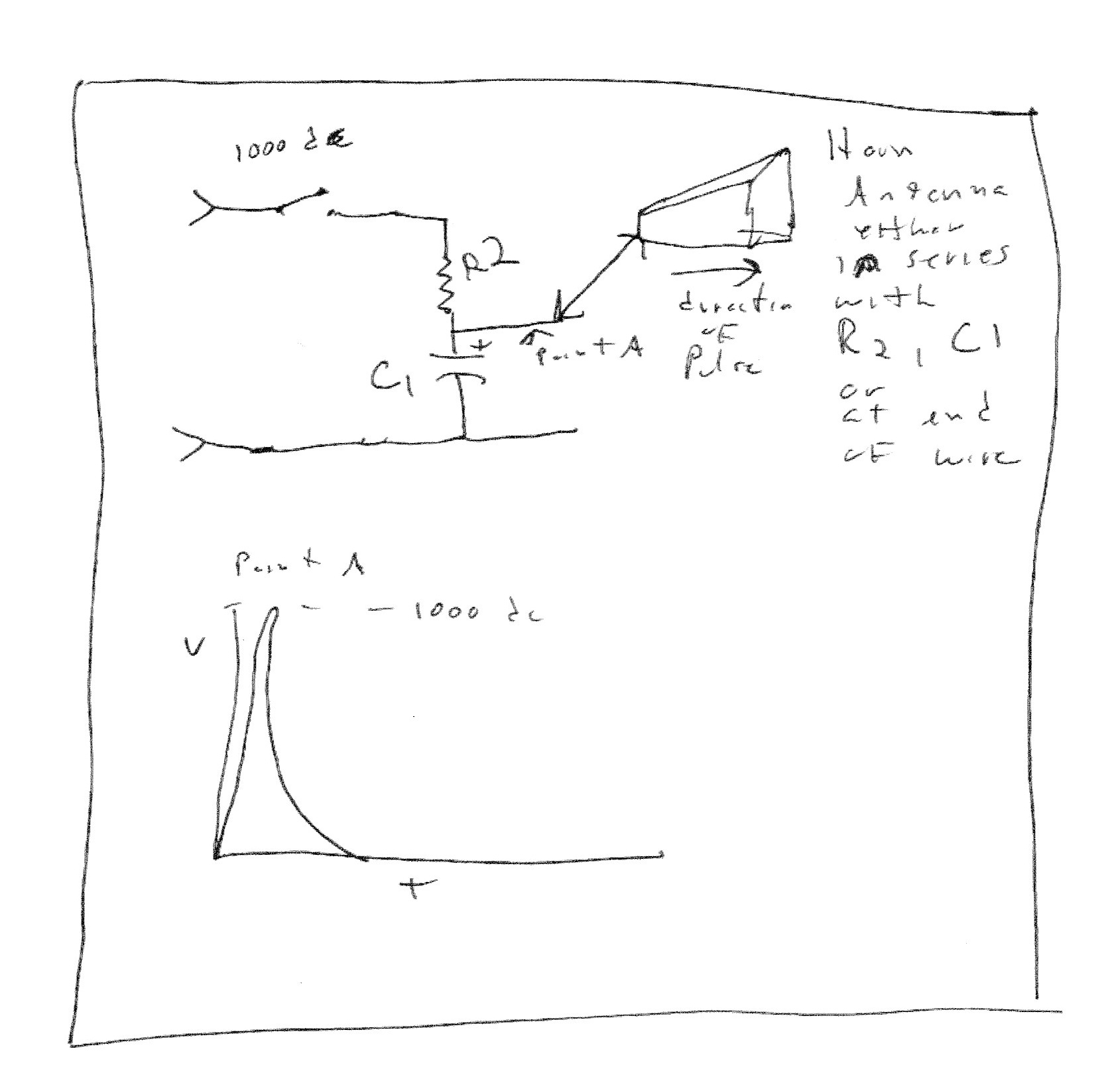

High Wattage Pulse Generator

Purpose - To disable in place neural implants and/or RFID chips placed under the scalp by

destroying micro-miniature electronic components with a high wattage pulse of

electromagnetic energy directed at the head. This process is in addition to TASERing

someone in the head or using ECT (electro convulsive therapy) or breaking an RFID chip

with a hammer.

Theory of Operation - The horn antenna is placed very near the head of the person with the implant or RFID chip. The device runs on ordinary household 120 AC from a wall outlet. The 120 AC is stepped up by a step-up transformer. That voltage is fed to a full wave bridge rectifier and then made into DC voltage by regulating capacitor and resistor. When switch 1 is thrown point-A immediately goes to maximum DC since capacitor is a dead short to DC voltage. Capacitor then charges to maximum DC voltage and point-A goes to zero voltage. The time for point-A to go from zero voltage to maximum voltage and back is determined by the equation T=RC. Since a high surge of current is desired, using a small value resistor makes for a very quick and powerful pulse of energy. If maximum DC voltage were 1000 volts a surge of 3000 Watts could be made with a resistor of 333 Ohms. A time of 1/2 a second could be made with a

1.5mF capacitor. High wattage components for this application might be hard to find, but

they do make capacitors for AC motors that are commercially available. They could be

bought at grainger.com.

I think it makes sense to both inject noise onto the wiring and filter it at the same time. Any device plugged in could be conducting surveillance. It could be using the AC wiring to communicate with the outside world. Generating noise inside the house could stop the device from picking anything up and injecting it onto the AC wiring can defeat it's transfer to the outside. Filtering at the same time can make sure.

Sidenote. Some people believe the HAARP facility in Alaska is used in mind control and surveillance. It's stated mission is communicating with submarines on Extremely Low Frequencies. (0 HZ to 100 HZ) In fact they think it operates around 30 HZ. It is possible to get high speed data to 'ride' on the 30 HZ. The 30 HZ might be powering the RFID chips and carrying the communication data.

High Wattage Pulse Generator

Purpose - To disable in place neural implants and/or RFID chips placed under the scalp by

destroying micro-miniature electronic components with a high wattage pulse of

electromagnetic energy directed at the head. This process is in addition to TASERing

someone in the head or using ECT (electro convulsive therapy) or breaking an RFID chip

with a hammer.

Theory of Operation - The horn antenna is placed very near the head of the person with the implant or RFID chip. The device runs on ordinary household 120 AC from a wall outlet. The 120 AC is stepped up by a step-up transformer. That voltage is fed to a full wave bridge rectifier and then made into DC voltage by regulating capacitor and resistor. When switch 1 is thrown point-A immediately goes to maximum DC since capacitor is a dead short to DC voltage. Capacitor then charges to maximum DC voltage and point-A goes to zero voltage. The time for point-A to go from zero voltage to maximum voltage and back is determined by the equation T=RC. Since a high surge of current is desired, using a small value resistor makes for a very quick and powerful pulse of energy. If maximum DC voltage were 1000 volts a surge of 3000 Watts could be made with a resistor of 333 Ohms. A time of 1/2 a second could be made with a

1.5mF capacitor. High wattage components for this application might be hard to find, but

they do make capacitors for AC motors that are commercially available. They could be

bought at grainger.com.

Problems - The schematic is over simplified. I am just trying to pass on an idea. A massive surge of current would probably draw down the DC voltage and seriously reduce wattage. A high power regulator would be needed. The capacitor would need to be discharged after each use to reset.

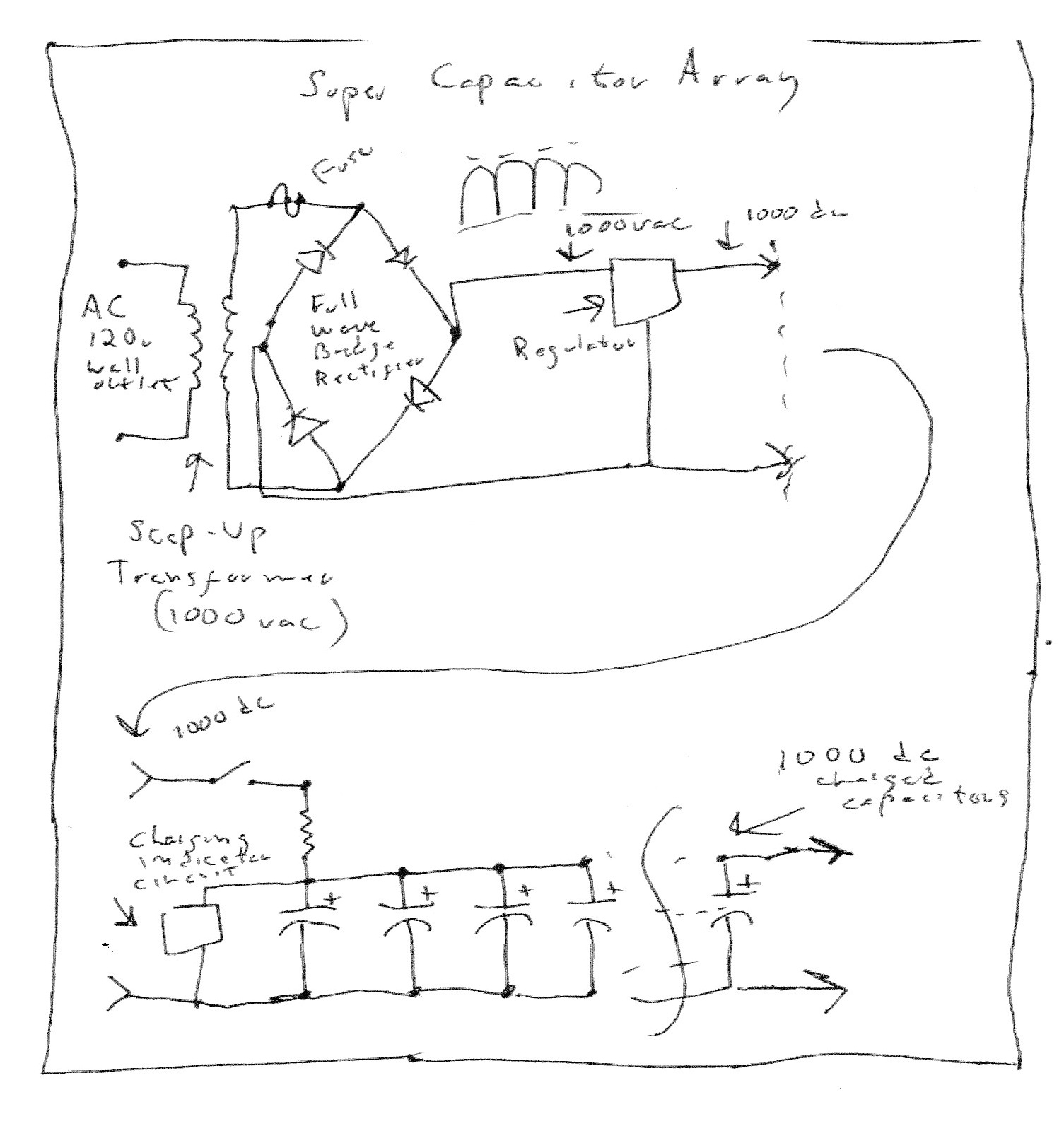

Addendum - This is an attempt to fix some of the issues brought up in the 'Problems' section above. The original design will pull down the DC voltage as the pulse rises. The overall wattage will be affected. This design adds an array of super-capacitors as a power source for the pulse. Super-capacitors are designed to hold a large amount of energy at high ratings such a 3500 volts. The definition of a capacitor is that it stores energy in an electric field. It can act something like a battery. It can be charged then discharged. The idea is to replace the AC supply and regulator with a an array of super capacitors. The capacitors are charged through a resistor. When the capacitors are fully charged an indicator circuit lights. The resistor and AC supply circuit can then be removed by throwing a switch. When ready, another switch is thrown to discharge the capacitors into the antenna circuit. After discharge the antenna circuit is switched out and the capacitors charged again.

Problems - The schematic is over simplified. I am just trying to pass on an idea. A massive surge of current would probably draw down the DC voltage and seriously reduce wattage. A high power regulator would be needed. The capacitor would need to be discharged after each use to reset.

Addendum - This is an attempt to fix some of the issues brought up in the 'Problems' section above. The original design will pull down the DC voltage as the pulse rises. The overall wattage will be affected. This design adds an array of super-capacitors as a power source for the pulse. Super-capacitors are designed to hold a large amount of energy at high ratings such a 3500 volts. The definition of a capacitor is that it stores energy in an electric field. It can act something like a battery. It can be charged then discharged. The idea is to replace the AC supply and regulator with a an array of super capacitors. The capacitors are charged through a resistor. When the capacitors are fully charged an indicator circuit lights. The resistor and AC supply circuit can then be removed by throwing a switch. When ready, another switch is thrown to discharge the capacitors into the antenna circuit. After discharge the antenna circuit is switched out and the capacitors charged again.

Note: Everything today runs on software. Even X-ray and MRI machines. If you took someone to a hospital or doctors office and had an X-ray or MRI it’s very possible that the software removed the implant from the result. I would do it again somewhere you know this won’t happen.

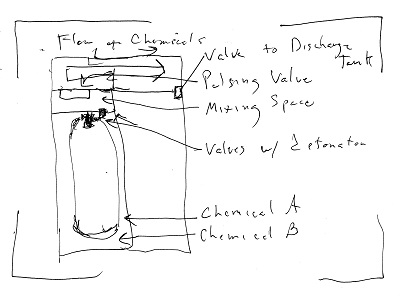

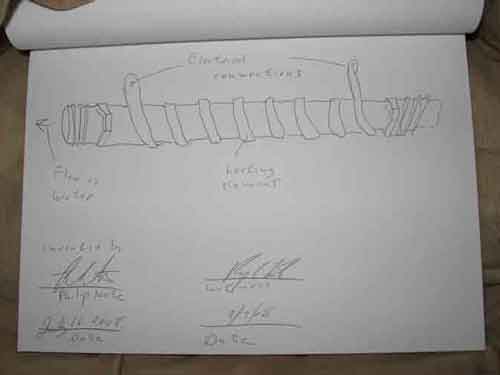

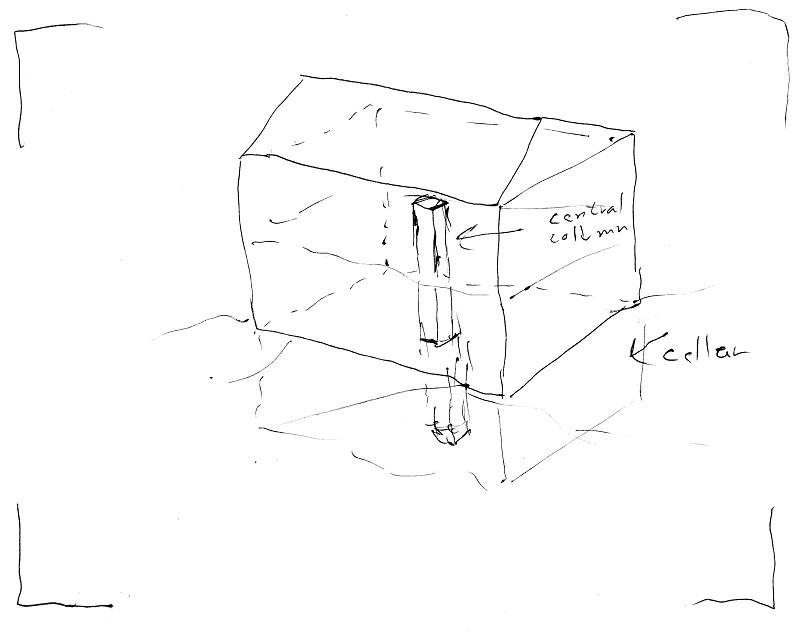

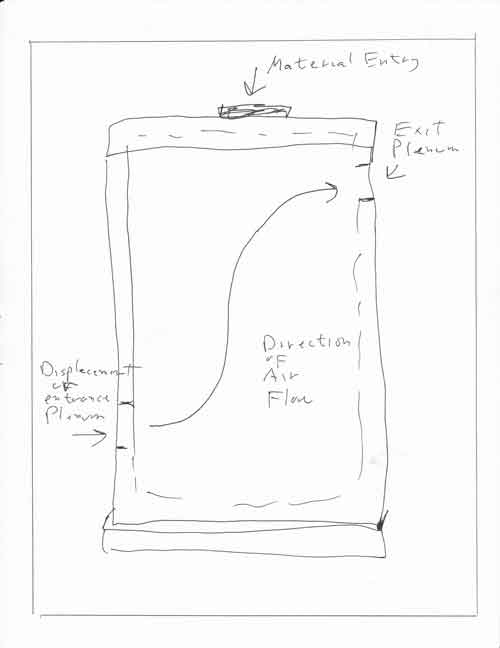

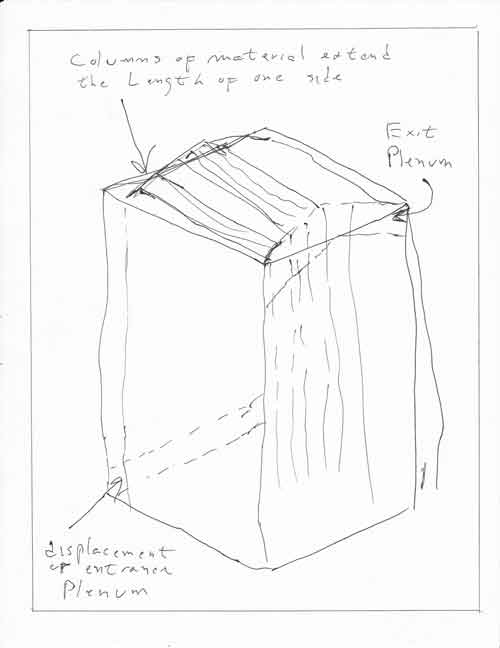

This is an idea for a mechanical/chemical high wattage pulse generator. (see drawings) Technically this would act like an AC battery and there is no such thing. But whatever. To produce electro-magnetic waves you must move the electrons in the piece of copper. The entire assembly would comprise 2 main parts. The first would be a large copper plate with a large piece of copper extending from the plate to act as an antenna and the second, an aluminum container with multiple compartments. (or glass with the top being aluminum) The compartments would hold the containers with the chemicals and valves. The chemicals would be discharged by a detonator into a mixing compartment. The mixing compartment would have a valve that pulses the mixture into the top compartment to stimulate the copper. The third compartment would initially be in a vacuum to pull the mixed chemicals from the top compartment as they are pulsed in. A separate valve between the top compartment and the vacuum would keep the pulses separate. The power and frequency could be controlled with the pressure of the chemicals and the rotation of the valves. A pulsing valve could be accomplished by using a fan in a cage with only a couple holes for air to pass and only one fan in the cage. Every time the holes line up, a pulse of chemicals enters the top compartment.

Note: Everything today runs on software. Even X-ray and MRI machines. If you took someone to a hospital or doctors office and had an X-ray or MRI it’s very possible that the software removed the implant from the result. I would do it again somewhere you know this won’t happen.

This is an idea for a mechanical/chemical high wattage pulse generator. (see drawings) Technically this would act like an AC battery and there is no such thing. But whatever. To produce electro-magnetic waves you must move the electrons in the piece of copper. The entire assembly would comprise 2 main parts. The first would be a large copper plate with a large piece of copper extending from the plate to act as an antenna and the second, an aluminum container with multiple compartments. (or glass with the top being aluminum) The compartments would hold the containers with the chemicals and valves. The chemicals would be discharged by a detonator into a mixing compartment. The mixing compartment would have a valve that pulses the mixture into the top compartment to stimulate the copper. The third compartment would initially be in a vacuum to pull the mixed chemicals from the top compartment as they are pulsed in. A separate valve between the top compartment and the vacuum would keep the pulses separate. The power and frequency could be controlled with the pressure of the chemicals and the rotation of the valves. A pulsing valve could be accomplished by using a fan in a cage with only a couple holes for air to pass and only one fan in the cage. Every time the holes line up, a pulse of chemicals enters the top compartment.

This is some of the theory behind it. Electric current is the actual movement of electrons in a conductive substance. Usually metal. The electrons move from one nucleus to another in a random fashion. A term for these electrons is valence electrons. The more valence electrons a substance has the more conductive it is. Electrons are negatively charged. A nucleus of an atom has both protons and neutrons, which are positively charged and electrically neutral respectively. As the electrons move they create electro-magnetic waves around the conductor. If the waves are varying in nature they can be picked up by a AC clamp meter. A clamp meter is basically a transformer that surrounds the conductor to measure its strength. It only works with AC waves, not DC. I don't know why. In electricity similar polarities repel each other and opposite polarities attract. The idea behind a battery is there is a buildup of electrons on one side and a depletion on the other. If you attach a circuit between current will flow. The battery dies when the electrons on one side have all drifted to the positive. In our universe gasses can be ionized. That is they can have a too many electrons or too few. Or they can be neutral. The PH of water is a measurement of it's ionization. The idea is to find a gas that can be heavily laden with electrons to make it negatively charged. That gas would be pulsed into a glass chamber where the copper plate is. When the copper plate is exposed to the highly charged gas it moves the electrons in the copper because similar polarities repel. If the gas is pulsed you will create a varying wave.

If you wanted to make some serious trouble with this idea you could mount it inside a truck and attach it to an aluminum frame. The frame would act as the antenna. Drive by a building (NSA) and blow it off and you might destroy whats inside.

Automobile companies won’t build electric cars because battery technology is too expensive and doesn’t hold enough energy to run a car very long. (or so they say) Have they looked into alternative methods for generating alternating current?

I downloaded both images below from ‘Google Images’ by typing in ‘neuro radio’.

This is some of the theory behind it. Electric current is the actual movement of electrons in a conductive substance. Usually metal. The electrons move from one nucleus to another in a random fashion. A term for these electrons is valence electrons. The more valence electrons a substance has the more conductive it is. Electrons are negatively charged. A nucleus of an atom has both protons and neutrons, which are positively charged and electrically neutral respectively. As the electrons move they create electro-magnetic waves around the conductor. If the waves are varying in nature they can be picked up by a AC clamp meter. A clamp meter is basically a transformer that surrounds the conductor to measure its strength. It only works with AC waves, not DC. I don't know why. In electricity similar polarities repel each other and opposite polarities attract. The idea behind a battery is there is a buildup of electrons on one side and a depletion on the other. If you attach a circuit between current will flow. The battery dies when the electrons on one side have all drifted to the positive. In our universe gasses can be ionized. That is they can have a too many electrons or too few. Or they can be neutral. The PH of water is a measurement of it's ionization. The idea is to find a gas that can be heavily laden with electrons to make it negatively charged. That gas would be pulsed into a glass chamber where the copper plate is. When the copper plate is exposed to the highly charged gas it moves the electrons in the copper because similar polarities repel. If the gas is pulsed you will create a varying wave.

If you wanted to make some serious trouble with this idea you could mount it inside a truck and attach it to an aluminum frame. The frame would act as the antenna. Drive by a building (NSA) and blow it off and you might destroy whats inside.

Automobile companies won’t build electric cars because battery technology is too expensive and doesn’t hold enough energy to run a car very long. (or so they say) Have they looked into alternative methods for generating alternating current?

I downloaded both images below from ‘Google Images’ by typing in ‘neuro radio’.

The 2 links are a presentation by Daryl R Kipke and a catalog from Neuro Nexus Tech a company owned by Daryl R Kipke.

Advanced Neural Implants And Control by Daryl R Kipke

Neuro Nexus Tech Probe Catalog

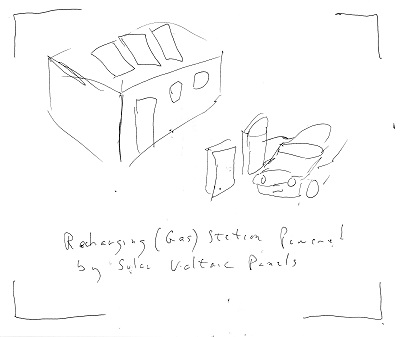

Jan 25 2018 - This is an addendum to the Mechanical/Chemical High Wattage Pulse Generator. I think this idea could be used to power automobiles. Instead of discharging the device once it could be recharged by stopping at a gas (re-charging) station run by solar voltaic panels. The contents of the vacuum side would be transferred back to the holding tank by a re-charging pump. The copper conductor would be surrounded by an iron toroid with a winding that acts like the secondary of a transformer. The AC would power AC motors that run the auto. The assembly would fit into the engine compartment.

The 2 links are a presentation by Daryl R Kipke and a catalog from Neuro Nexus Tech a company owned by Daryl R Kipke.

Advanced Neural Implants And Control by Daryl R Kipke

Neuro Nexus Tech Probe Catalog

Jan 25 2018 - This is an addendum to the Mechanical/Chemical High Wattage Pulse Generator. I think this idea could be used to power automobiles. Instead of discharging the device once it could be recharged by stopping at a gas (re-charging) station run by solar voltaic panels. The contents of the vacuum side would be transferred back to the holding tank by a re-charging pump. The copper conductor would be surrounded by an iron toroid with a winding that acts like the secondary of a transformer. The AC would power AC motors that run the auto. The assembly would fit into the engine compartment.

Noise Generator

Electro-magnetic interference (EMI) happens when one electrical device interferes with another. Engineers are required by law to limit a devices EMI. You can't sell a TV that interferes with a DVD player and vice versa. EMI could also be described as electro-magnetic noise. Generating noise on purpose can be useful. A separate noise device can be used to test a devices immunity to it. Ham radio noise generators can be bought on the internet. Noise can be used to jam radio's if it is at the operating frequency of the receiver and of a higher wattage. When used as a jamming device it is always aimed at the receiver. A satellite could be considered a receiver as it is 'picking up' electro-magnetic waves on the earth. There are numerous ways to generate noise. It can be difficult to generate it over the entire frequency spectrum.

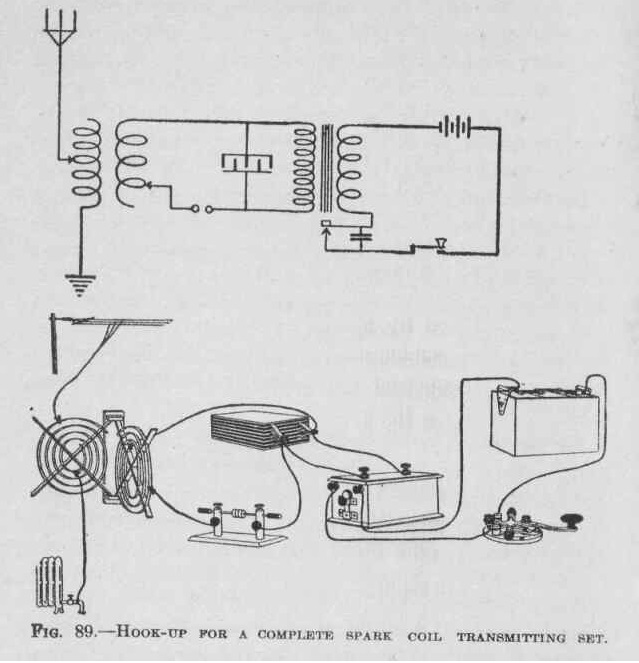

The frequency spectrum is considered from DC (0hz) to about 3thz (terra hz 3,000,000,000,000). Anything above that is considered light. One of the first radios was the best way to jam the entire spectrum. The spark transmitter. A spark transmitter was used on the Titanic. It was invented by Nikola Tesla who also invented most the AC generating and distribution system we use today. A spark transmitter generates a very high wattage spark like lightning and radiates that on an antenna. A 'spark', or lightning, is plasma, the fourth state of matter. The other 3 are gas, liquid and solid. Spark transmitters were outlawed specifically because they interfered with everything. The picture below is a simplified example.

Noise Generator

Electro-magnetic interference (EMI) happens when one electrical device interferes with another. Engineers are required by law to limit a devices EMI. You can't sell a TV that interferes with a DVD player and vice versa. EMI could also be described as electro-magnetic noise. Generating noise on purpose can be useful. A separate noise device can be used to test a devices immunity to it. Ham radio noise generators can be bought on the internet. Noise can be used to jam radio's if it is at the operating frequency of the receiver and of a higher wattage. When used as a jamming device it is always aimed at the receiver. A satellite could be considered a receiver as it is 'picking up' electro-magnetic waves on the earth. There are numerous ways to generate noise. It can be difficult to generate it over the entire frequency spectrum.

The frequency spectrum is considered from DC (0hz) to about 3thz (terra hz 3,000,000,000,000). Anything above that is considered light. One of the first radios was the best way to jam the entire spectrum. The spark transmitter. A spark transmitter was used on the Titanic. It was invented by Nikola Tesla who also invented most the AC generating and distribution system we use today. A spark transmitter generates a very high wattage spark like lightning and radiates that on an antenna. A 'spark', or lightning, is plasma, the fourth state of matter. The other 3 are gas, liquid and solid. Spark transmitters were outlawed specifically because they interfered with everything. The picture below is a simplified example.

A spark transmitter works by building up a massive store of energy in either a capacitor or inductor then discharging the energy quickly across a gap such as an automobile spark plug. The next picture is a rig I built. I mounted an ordinary lawn mower spark plug in a piece of metal and mounted it on a board. I bought an auto transformer on Amazon as the coil. It works like a regular car generator.

A spark transmitter works by building up a massive store of energy in either a capacitor or inductor then discharging the energy quickly across a gap such as an automobile spark plug. The next picture is a rig I built. I mounted an ordinary lawn mower spark plug in a piece of metal and mounted it on a board. I bought an auto transformer on Amazon as the coil. It works like a regular car generator.

Other ways of using plasma are vacuum tubes and Nixie tubes. Vacuum tubes were used extensively before silicon transistors. Plasma is generated in a vacuum to make it less noisy and dangerous. It might be possible to use one, I don't know I didn't try. They still make them because they make cheap and reliable parts for very high power applications. Nixie tubes were the first electronic displays. They're sort of a neon technology for electronics. They can be hard to find.

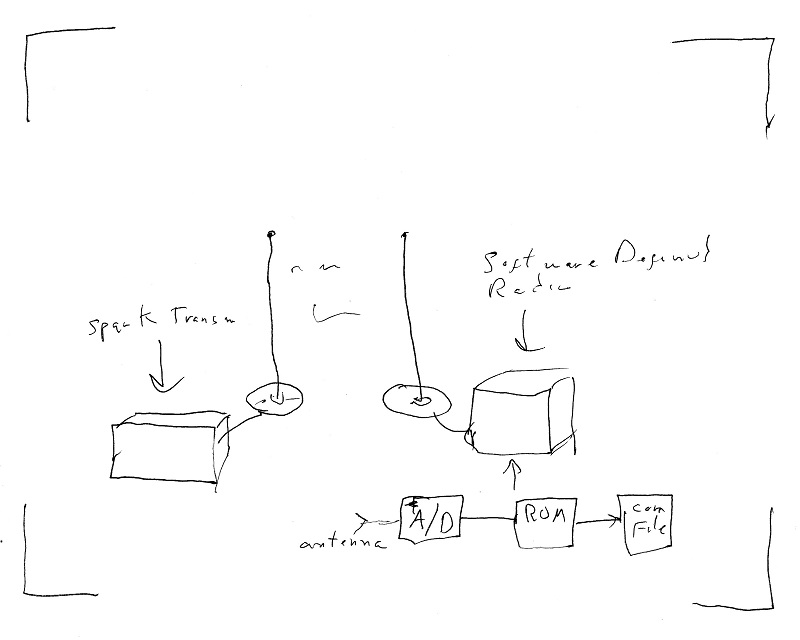

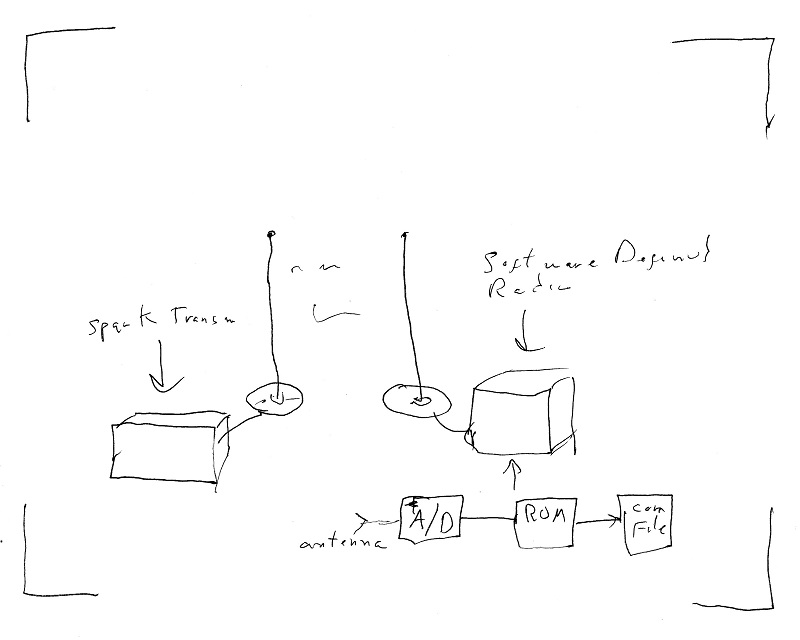

I think it's possible to record the output of a spark transmitter and make a computer file out of it. Transfer the file to a small ROM chip and use it in a carry around device. Instead of analog to digital it would go digital to analog.

Other ways of using plasma are vacuum tubes and Nixie tubes. Vacuum tubes were used extensively before silicon transistors. Plasma is generated in a vacuum to make it less noisy and dangerous. It might be possible to use one, I don't know I didn't try. They still make them because they make cheap and reliable parts for very high power applications. Nixie tubes were the first electronic displays. They're sort of a neon technology for electronics. They can be hard to find.

I think it's possible to record the output of a spark transmitter and make a computer file out of it. Transfer the file to a small ROM chip and use it in a carry around device. Instead of analog to digital it would go digital to analog.

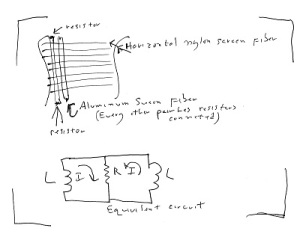

Bluetooth is a technology that allows devices to work wirelessly within a very small area. Bluetooth devices won't work beyond say 10 ft. (I'm not sure what the actual specification is) The power level any Bluetooth device produces is very small so it won't interfere with other wireless devices nearby. Personal Area Jamming devices could work at the same power level to jam your personal emissions. Any noise circuit could be attached to a necklace used for an antenna and then carried around in your pocket. Below is a picture of a piece of sterling silver Viking Weave with an electrical connector on one end. Viking Weave is one continuous piece of silver and would work well as an a antenna.

Bluetooth is a technology that allows devices to work wirelessly within a very small area. Bluetooth devices won't work beyond say 10 ft. (I'm not sure what the actual specification is) The power level any Bluetooth device produces is very small so it won't interfere with other wireless devices nearby. Personal Area Jamming devices could work at the same power level to jam your personal emissions. Any noise circuit could be attached to a necklace used for an antenna and then carried around in your pocket. Below is a picture of a piece of sterling silver Viking Weave with an electrical connector on one end. Viking Weave is one continuous piece of silver and would work well as an a antenna.

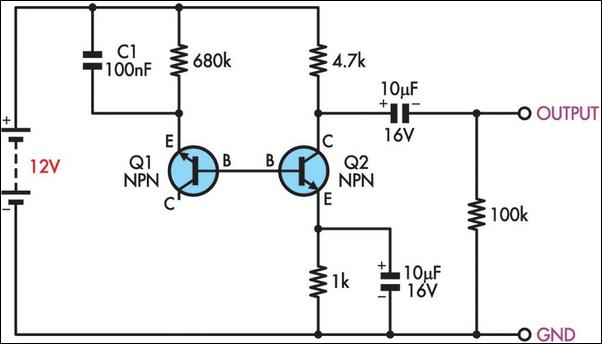

Solid state noise generators can be made in a couple ways. Avalanche, or shot, noise and circuits that produce pink, flicker, white and other types. Shot noise is produced by semiconductor PN junctions naturally. It can be drawn from the cathode of a Zener diode or a BJT transistor. (see below) Wikipedia describes shot noise in terms of probability. This is how I understand it. Current is the actual movement of electrons in a conductor. Electron movement is random whether it's AC or DC. The electrons drift from one nucleus to another randomly producing electro-magnetic waves as they go. Small currents are more random than large ones simply because there are fewer electrons. Circuits exist that produce noise without the shot phenomena. (see bottom picture)

Solid state noise generators can be made in a couple ways. Avalanche, or shot, noise and circuits that produce pink, flicker, white and other types. Shot noise is produced by semiconductor PN junctions naturally. It can be drawn from the cathode of a Zener diode or a BJT transistor. (see below) Wikipedia describes shot noise in terms of probability. This is how I understand it. Current is the actual movement of electrons in a conductor. Electron movement is random whether it's AC or DC. The electrons drift from one nucleus to another randomly producing electro-magnetic waves as they go. Small currents are more random than large ones simply because there are fewer electrons. Circuits exist that produce noise without the shot phenomena. (see bottom picture)

Zener Diode 1N759 provides the source of shot noise

Zener Diode 1N759 provides the source of shot noise

NPN Q1 provides the source of shot noise

NPN Q1 provides the source of shot noise

Shot, white, pink and other solid state circuits have certain problems. Many don't produce intense noise over a wide range of frequencies. Shot noise needs to be amplified. Noise such as white and pink are mostly in the audio range and are very uniform. That is, not very random. I think that modern software controlled radio can remove this type very easily. It would be better if someone could come up with a circuit to break up the signal then combine them through a mixer circuit. Shot noise could also be generated multiple times then combined with a mixer to make it more intense and difficult to filter. Modern synthesizers used in music have advanced circuits that manipulate frequency and amplitude. Studying those circuits might help.

Shot, white, pink and other solid state circuits have certain problems. Many don't produce intense noise over a wide range of frequencies. Shot noise needs to be amplified. Noise such as white and pink are mostly in the audio range and are very uniform. That is, not very random. I think that modern software controlled radio can remove this type very easily. It would be better if someone could come up with a circuit to break up the signal then combine them through a mixer circuit. Shot noise could also be generated multiple times then combined with a mixer to make it more intense and difficult to filter. Modern synthesizers used in music have advanced circuits that manipulate frequency and amplitude. Studying those circuits might help.

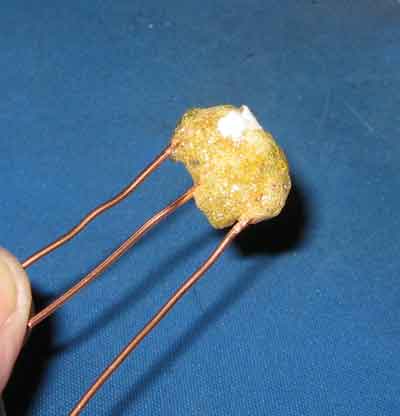

As a technician I know that some metals conduct electricity better than others. A signal put through a cold solder joint can be significantly altered. I think it's possible to create a component out of a metal or alloy that is a bad conductor of electricity and create noise. A way to find a metal would be to hook various wire up to a ham radio transmitter and see how noisy the result is. (see picture below) One metal I know is a bad conductor is iron. Maybe an alloy of iron and silver or copper. I think a component could be made of the metal and the output amplified and transmitted normally.

As a technician I know that some metals conduct electricity better than others. A signal put through a cold solder joint can be significantly altered. I think it's possible to create a component out of a metal or alloy that is a bad conductor of electricity and create noise. A way to find a metal would be to hook various wire up to a ham radio transmitter and see how noisy the result is. (see picture below) One metal I know is a bad conductor is iron. Maybe an alloy of iron and silver or copper. I think a component could be made of the metal and the output amplified and transmitted normally.

This is another idea for a noise generator. Electronic music is notorious for feedback. Feedback happens when the pickup on a guitar is vibrated by the very sound coming out of it (the amplifier). The idea is to have 2 antennas very close to each other. One to transmit the other to receive. The receive circuitry would be fed back to the transmit circuitry and controlled by some random control circuit.

This is another idea for a noise generator. Electronic music is notorious for feedback. Feedback happens when the pickup on a guitar is vibrated by the very sound coming out of it (the amplifier). The idea is to have 2 antennas very close to each other. One to transmit the other to receive. The receive circuitry would be fed back to the transmit circuitry and controlled by some random control circuit.

Recycling Electronic Parts

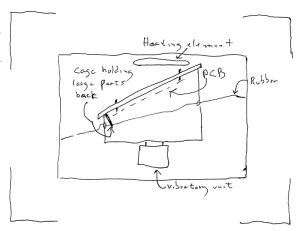

This is an idea for budding revolutionary’s. Modern army’s are heavily dependent on technology. Electronics is a major force in warfare and it’s cost is prohibitive to people at the bottom trying to fight back. This idea might help reduce the cost of experimenting and building technology. When I first started in electronics printed circuit boards (PCB) were assembled with parts that were called ‘through hole’. The leads of the various parts were put through a hole in the PCB and soldered on the opposite side. There was a component side and a solder side. Getting parts in and out of the PCB was difficult. Today almost everything is surface mount technology (SMT). The parts are soldered on the component side. Hobbyists have found it difficult to work and experiment with SMT but it can be done. I think getting the parts off the PCB could be fairly simple as opposed to through hole PCB's. Using a vibratory could be helpful. A vibratory uses some sort of transformer principle to vibrate. The idea is this. Build a small enclosure 20 inches by 20 inches by 10 inches tall that will withstand high heat. Place a very small vibratory unit in the bottom that can be adjusted for small vibration or large. Above the vibratory, in the middle of the enclosure, place some rubber at a steep angle. Attach to the vibratory, above the rubber and at a steep angle, a harness that will hold the PCB being stripped of components upside down. Place a heating element in the upper part of the enclosure that will heat the entire space enough to melt electric solder. As the temperature of the enclosure rises the PCB is vibrated and the parts fall in the rubber along with residual solder. The only parts of any real value are the largest IC’s. Part of the harness holding the PCB should have a cage of plastic to separate the large parts from the small and remove the residual solder. (see picture)

Recycling Electronic Parts

This is an idea for budding revolutionary’s. Modern army’s are heavily dependent on technology. Electronics is a major force in warfare and it’s cost is prohibitive to people at the bottom trying to fight back. This idea might help reduce the cost of experimenting and building technology. When I first started in electronics printed circuit boards (PCB) were assembled with parts that were called ‘through hole’. The leads of the various parts were put through a hole in the PCB and soldered on the opposite side. There was a component side and a solder side. Getting parts in and out of the PCB was difficult. Today almost everything is surface mount technology (SMT). The parts are soldered on the component side. Hobbyists have found it difficult to work and experiment with SMT but it can be done. I think getting the parts off the PCB could be fairly simple as opposed to through hole PCB's. Using a vibratory could be helpful. A vibratory uses some sort of transformer principle to vibrate. The idea is this. Build a small enclosure 20 inches by 20 inches by 10 inches tall that will withstand high heat. Place a very small vibratory unit in the bottom that can be adjusted for small vibration or large. Above the vibratory, in the middle of the enclosure, place some rubber at a steep angle. Attach to the vibratory, above the rubber and at a steep angle, a harness that will hold the PCB being stripped of components upside down. Place a heating element in the upper part of the enclosure that will heat the entire space enough to melt electric solder. As the temperature of the enclosure rises the PCB is vibrated and the parts fall in the rubber along with residual solder. The only parts of any real value are the largest IC’s. Part of the harness holding the PCB should have a cage of plastic to separate the large parts from the small and remove the residual solder. (see picture)

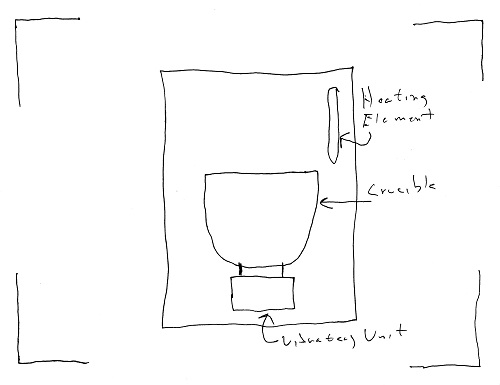

Once the PCB has had all the parts removed it’s not worth anything except for the metal. I think it’s possible to separate and recover some of the metal. Build an enclosure with a grinding wheel that is airtight. Automatically feed the PCB into the grinding wheel turning it to dust. Blow the dust into another enclosure where a gas flame burns away the fiberglass in the dust. Collect the metal. Build an enclosure with a crucible attached to a vibratory and put the remaining dust in the crucible. Different metals have different melting points. Slowly raise the temperature until the first melting point is reached. Vibrate the crucible to help whatever metal is in the dust bead together. Remove the heat, open the enclosure, and remove what metal has collected and repeat the process at the next highest temperature. (see picture)

Once the PCB has had all the parts removed it’s not worth anything except for the metal. I think it’s possible to separate and recover some of the metal. Build an enclosure with a grinding wheel that is airtight. Automatically feed the PCB into the grinding wheel turning it to dust. Blow the dust into another enclosure where a gas flame burns away the fiberglass in the dust. Collect the metal. Build an enclosure with a crucible attached to a vibratory and put the remaining dust in the crucible. Different metals have different melting points. Slowly raise the temperature until the first melting point is reached. Vibrate the crucible to help whatever metal is in the dust bead together. Remove the heat, open the enclosure, and remove what metal has collected and repeat the process at the next highest temperature. (see picture)

On Dec 30 and 31 2017 I posted 3 videos on youtube titled “Re-using Surface Mount Parts 1” (2 and 3). My account can be found at “www.youtube.com/zsezse215”. If no one else sees them it's proof my internet connection is censored. This is a summary of what is in them.

On my main blog “www.philipnute.wordpress.com”, I propose an invention 'Recycling Parts'. I want to try to prove that surface mount parts can be removed and reused. The top picture is what's left of a cell phone I found while out walking. Initially the 4 metal pieces were covering the main integrated circuits. I had some difficulty removing them. I eventually cut the PCB up into smaller pieces and managed to remove them without too much trouble.

On Dec 30 and 31 2017 I posted 3 videos on youtube titled “Re-using Surface Mount Parts 1” (2 and 3). My account can be found at “www.youtube.com/zsezse215”. If no one else sees them it's proof my internet connection is censored. This is a summary of what is in them.

On my main blog “www.philipnute.wordpress.com”, I propose an invention 'Recycling Parts'. I want to try to prove that surface mount parts can be removed and reused. The top picture is what's left of a cell phone I found while out walking. Initially the 4 metal pieces were covering the main integrated circuits. I had some difficulty removing them. I eventually cut the PCB up into smaller pieces and managed to remove them without too much trouble.

The chip I want to remove this time is in the picture below. It's a Qualcomm MSM 8909 SnapDragon SOS (system on a chip).

The chip I want to remove this time is in the picture below. It's a Qualcomm MSM 8909 SnapDragon SOS (system on a chip).

Cutting up the PCB had at least 1 advantage. It's like heating up a large frying pan or small frying pan with the same size burner. The small frying pan will heat up faster. Trying to heat up the entire PCB will take away some of the heat I am trying to concentrate on the chip. The same principle applies to the soldering hands. The alligator clips are made of metal. If the piece of PCB is too close to the alligator clip you will be heating up the clip and taking away from the area near the chip.

Cutting up the PCB had at least 1 advantage. It's like heating up a large frying pan or small frying pan with the same size burner. The small frying pan will heat up faster. Trying to heat up the entire PCB will take away some of the heat I am trying to concentrate on the chip. The same principle applies to the soldering hands. The alligator clips are made of metal. If the piece of PCB is too close to the alligator clip you will be heating up the clip and taking away from the area near the chip.

The idea is to apply heat with an ordinary heat gun, to the underside of the PCB until the solder melts on the other side. While applying heat I will tap the soldering hands on the bench until the chip falls off. Heat guns can be bought at any home improvement store. They are used to remove paint. They are also used in electronics for shrink wrap. My gun goes up to 650 degrees F which is well above the melting point of electrical solder.

The idea is to apply heat with an ordinary heat gun, to the underside of the PCB until the solder melts on the other side. While applying heat I will tap the soldering hands on the bench until the chip falls off. Heat guns can be bought at any home improvement store. They are used to remove paint. They are also used in electronics for shrink wrap. My gun goes up to 650 degrees F which is well above the melting point of electrical solder.

It took about 2 minutes before the chip came off. I don't know if it's usable or not. Maybe something was wrong with the phone when I found it. Too much heat can destroy small IC's. I could get a temperature probe and make sure I'm not overheating it but I just wanted to prove it could be done. Once it's off I could re-solder it to a surface mount adapter and power it up.

It took about 2 minutes before the chip came off. I don't know if it's usable or not. Maybe something was wrong with the phone when I found it. Too much heat can destroy small IC's. I could get a temperature probe and make sure I'm not overheating it but I just wanted to prove it could be done. Once it's off I could re-solder it to a surface mount adapter and power it up.

Surface mount adapters come in all sizes. The picture below is a sample.

Surface mount adapters come in all sizes. The picture below is a sample.

Printed Circuit Board Manufacturing

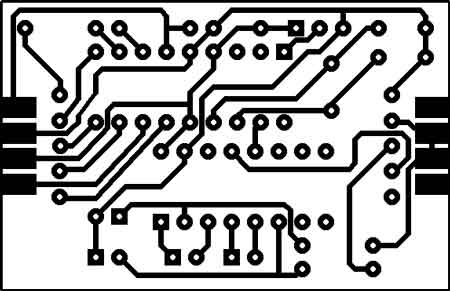

The old way of making blank printed circuit boards requires a lot of chemicals and machinery. Chemicals include acids, electroplating solutions and photo resist. The processes include photography, ultraviolet light, etching with acids, drilling holes, and electroplating. It’s dirty, time consuming and inexact. Components must be added later with different machines. Many of the chemicals are oil based. It is very labor intensive. Companies sometimes employ hundreds of people to inspect the boards for shorts and opens. The picture below is a blank copper board.

Printed Circuit Board Manufacturing

The old way of making blank printed circuit boards requires a lot of chemicals and machinery. Chemicals include acids, electroplating solutions and photo resist. The processes include photography, ultraviolet light, etching with acids, drilling holes, and electroplating. It’s dirty, time consuming and inexact. Components must be added later with different machines. Many of the chemicals are oil based. It is very labor intensive. Companies sometimes employ hundreds of people to inspect the boards for shorts and opens. The picture below is a blank copper board.

The top three pictures are examples. The top picture is an artwork. The artwork must be converted to a photo negative. A blank board is covered with photo-resist. The negative is placed on top and exposed to ultra-violet light. The photo resist that is exposed to ultra violet hardens and will not come off during the first washing with acid thus leaving the copper connections. The board is then washed with another type of acid removing all the photo resist. The second picture is a board without the components and the third with.

The top three pictures are examples. The top picture is an artwork. The artwork must be converted to a photo negative. A blank board is covered with photo-resist. The negative is placed on top and exposed to ultra-violet light. The photo resist that is exposed to ultra violet hardens and will not come off during the first washing with acid thus leaving the copper connections. The board is then washed with another type of acid removing all the photo resist. The second picture is a board without the components and the third with.

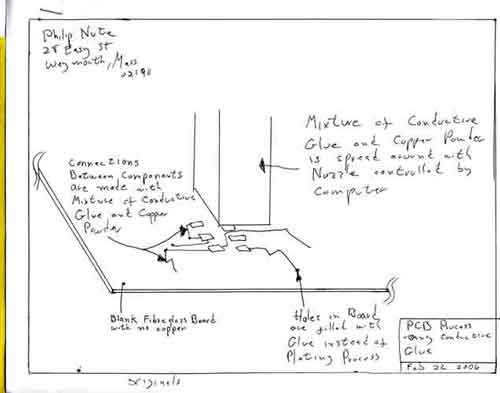

In one idea a cutting bit cuts the connections. Connections are passed from bottom to top by inserting and soldering wire. The other idea is to spread a conductive substance around, something like the car defogger, with a computer. The advantages are many. Faster manufacturing time, less cost, fewer chemicals and more exact. R and D can be sped up.

In one idea a cutting bit cuts the connections. Connections are passed from bottom to top by inserting and soldering wire. The other idea is to spread a conductive substance around, something like the car defogger, with a computer. The advantages are many. Faster manufacturing time, less cost, fewer chemicals and more exact. R and D can be sped up.

For most people PCB layout and etching services are beyond their pocketbook and when developing new products etching services are even more expensive because of the low number of PCB’s ordered. This is a way to avoid all services and `at the same time and speed up your R&D. The pictures below are 1. a Dremel stand 2. Copper coated blank G10. and 3. a x-y table for drill press. A Dremel is a common household tool sold almost anywhere tools are sold. It can be fitted with drills carving bits sand paper etc. The top picture is a Dremel stand (sold separately from the Dremel) that can be an accurate drill press for drilling holes in your PCB (G10 blank copper). The middle picture is of G10 blank copper. The third picture is a low profile x-y table that could be positioned under the Dremel stand, it could hold the G10 and be used to ‘carve’ away the copper instead of etching. You would have to do your own layout but building the actual prototype would be much faster and cheaper.

For most people PCB layout and etching services are beyond their pocketbook and when developing new products etching services are even more expensive because of the low number of PCB’s ordered. This is a way to avoid all services and `at the same time and speed up your R&D. The pictures below are 1. a Dremel stand 2. Copper coated blank G10. and 3. a x-y table for drill press. A Dremel is a common household tool sold almost anywhere tools are sold. It can be fitted with drills carving bits sand paper etc. The top picture is a Dremel stand (sold separately from the Dremel) that can be an accurate drill press for drilling holes in your PCB (G10 blank copper). The middle picture is of G10 blank copper. The third picture is a low profile x-y table that could be positioned under the Dremel stand, it could hold the G10 and be used to ‘carve’ away the copper instead of etching. You would have to do your own layout but building the actual prototype would be much faster and cheaper.

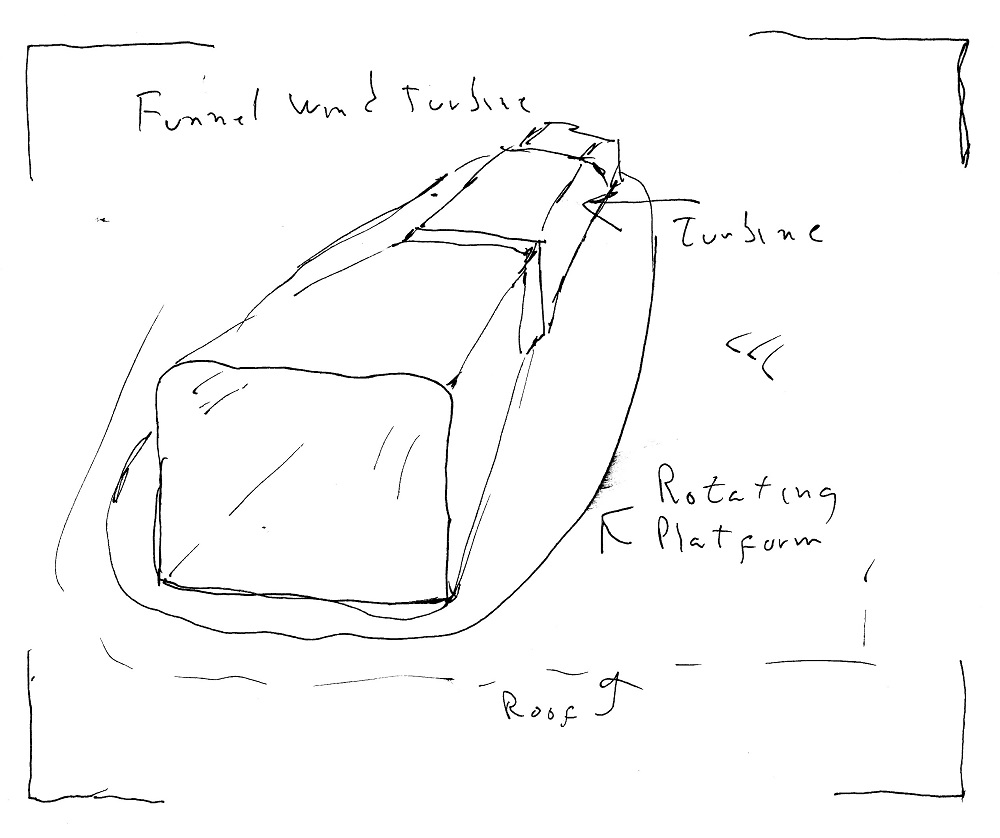

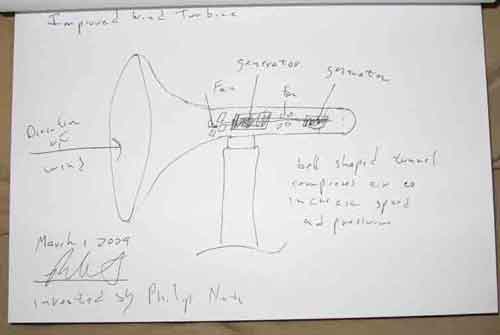

Software Defined Universal Electronic Input Output Device

Having an oscilloscope, spectrum analyzer and a function generator that operates from DC to well into microwaves could be very useful. It is probably very expensive to purchase these if they would sell them to you which they wouldn't if they knew what you were going to do with them. I think it would also be useful to have a radio that can receive and transmit anything from DC to microwaves in every type of modulation. It could be used as an alternative relay communication system. It would be helpful to generate all kinds of noise from DC to microwaves at the same time. I think this could all be accomplished with one device I call a Software Defined Universal Electronic Input Output Device.

Software Defined Radio is the latest thing in ham radio so much of the technology already exists. The pictures below is something I've been working on. I bought these parts from tapr.org (Tucson ) I found that website through hpsdr.com. (high performance software defined radio) It consists of a backplane mounted in an aluminum enclosure with a fan and a separate enclosure for an RF front end. The backplane has a standard ATX12v connector for power. It will supply +12v, -12v, +5v, -5v and 3.3v to every board plugged in. You can build whatever you want in each slot.

Software Defined Radio (SDR) uses the latest technology in digital signal processing (DSP). DSP can go two ways, analog to digital and digital to analog. Analog to digital converts any signal to a stream of digital data that can be operated on by a computer. Digital to analog has the computer create the data stream and convert it to an analog signal. This can all be accomplished with a personal computer and a universal electronic device.

Software Defined Universal Electronic Input Output Device

Having an oscilloscope, spectrum analyzer and a function generator that operates from DC to well into microwaves could be very useful. It is probably very expensive to purchase these if they would sell them to you which they wouldn't if they knew what you were going to do with them. I think it would also be useful to have a radio that can receive and transmit anything from DC to microwaves in every type of modulation. It could be used as an alternative relay communication system. It would be helpful to generate all kinds of noise from DC to microwaves at the same time. I think this could all be accomplished with one device I call a Software Defined Universal Electronic Input Output Device.

Software Defined Radio is the latest thing in ham radio so much of the technology already exists. The pictures below is something I've been working on. I bought these parts from tapr.org (Tucson ) I found that website through hpsdr.com. (high performance software defined radio) It consists of a backplane mounted in an aluminum enclosure with a fan and a separate enclosure for an RF front end. The backplane has a standard ATX12v connector for power. It will supply +12v, -12v, +5v, -5v and 3.3v to every board plugged in. You can build whatever you want in each slot.

Software Defined Radio (SDR) uses the latest technology in digital signal processing (DSP). DSP can go two ways, analog to digital and digital to analog. Analog to digital converts any signal to a stream of digital data that can be operated on by a computer. Digital to analog has the computer create the data stream and convert it to an analog signal. This can all be accomplished with a personal computer and a universal electronic device.

Since starting this project I have discovered backplane's are made as a standard part as well as the power supplies that come with them. One supplier is Vector Electronics based in Los Angeles. There are companies that make development kits that come with everything you need. The various engineering societies have produced standards for buses used on backplanes. IEEE, IEC and ANSI. One such standard is a VME bus IEEE 1014. I found a kit at elma.com. Model VITA Type 15 4U Rackmount Desktop.

Updated Sept 6 2017

This is a rough idea of what the RF front end (input circuit) would look like. The original signal would come in on either an antenna or an oscilloscope probe. The original signal would never go through any parts, passive or active. The various factors needed for the computer software (ie frequency, voltage, current etc) would be taken off the original signal bus then turned into digital data. All the digital data would go into a parallel to serial converter and transferred to the PC on the USB serial bus. I figure it doesn't matter what data you transfer, if you don't need it for a particular software application then don't use it.

Since starting this project I have discovered backplane's are made as a standard part as well as the power supplies that come with them. One supplier is Vector Electronics based in Los Angeles. There are companies that make development kits that come with everything you need. The various engineering societies have produced standards for buses used on backplanes. IEEE, IEC and ANSI. One such standard is a VME bus IEEE 1014. I found a kit at elma.com. Model VITA Type 15 4U Rackmount Desktop.

Updated Sept 6 2017

This is a rough idea of what the RF front end (input circuit) would look like. The original signal would come in on either an antenna or an oscilloscope probe. The original signal would never go through any parts, passive or active. The various factors needed for the computer software (ie frequency, voltage, current etc) would be taken off the original signal bus then turned into digital data. All the digital data would go into a parallel to serial converter and transferred to the PC on the USB serial bus. I figure it doesn't matter what data you transfer, if you don't need it for a particular software application then don't use it.

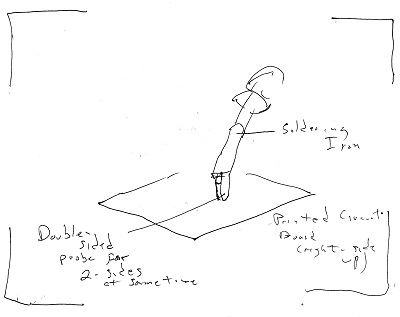

Soldering Iron Attachment

This is an idea for hobbyists who fool around with electronics or hackers who fool around with the government. You know what a pain it is to work with surface mount components. It’s difficult to get them on and off boards. Any ordinary soldering iron will have replaceable tips. Tips come in different sizes and shapes. The shaft that holds the tip can get as hot as the tip itself so the idea is to fashion a piece of metal to slip over the shaft. You can make the end of the metal any shape you want. The top picture is one I made that I never did anything with. I could cut a square hole in it the exact shape of an IC and heat up every pin at the same time. (second picture) By holding the board upside-down I could get the chip off without too much effort. Sometimes it’s good to heat up both ends of a resistor at the same time. (see bottom picture) Small pieces of sheet metal can be bought from any hardware store. I think ?? (I’m not sure) stainless will not accept solder. The lighter the gauge the better, because it will be easier to heat up.

Soldering Iron Attachment

This is an idea for hobbyists who fool around with electronics or hackers who fool around with the government. You know what a pain it is to work with surface mount components. It’s difficult to get them on and off boards. Any ordinary soldering iron will have replaceable tips. Tips come in different sizes and shapes. The shaft that holds the tip can get as hot as the tip itself so the idea is to fashion a piece of metal to slip over the shaft. You can make the end of the metal any shape you want. The top picture is one I made that I never did anything with. I could cut a square hole in it the exact shape of an IC and heat up every pin at the same time. (second picture) By holding the board upside-down I could get the chip off without too much effort. Sometimes it’s good to heat up both ends of a resistor at the same time. (see bottom picture) Small pieces of sheet metal can be bought from any hardware store. I think ?? (I’m not sure) stainless will not accept solder. The lighter the gauge the better, because it will be easier to heat up.

Spark Transmitter

Spark generators were one of the first Morse Code machines. They were invented by Nikola Tesla before the end of the 19th century. The Titanic carried a spark transmitter (generator). As radio progressed they were outlawed because they interfered with the entire radio spectrum. A Jacobs Ladder is a type of spark generator. At high voltages they can interrupt everything. A basic spark transmitter can be built from off the shelf parts. I mounted a standard spark plug from an internal combustion engine in a piece of metal and mounted that on a board. To create the spark I used a standard ignition coil with a Velleman kit. The Velleman kit (K2543) comes with everything needed, but it has to be assembled. The coil is an auto-transformer that can be bought on Amazon. Auto-transformers are used in cars to generate the spark.

Spark Transmitter

Spark generators were one of the first Morse Code machines. They were invented by Nikola Tesla before the end of the 19th century. The Titanic carried a spark transmitter (generator). As radio progressed they were outlawed because they interfered with the entire radio spectrum. A Jacobs Ladder is a type of spark generator. At high voltages they can interrupt everything. A basic spark transmitter can be built from off the shelf parts. I mounted a standard spark plug from an internal combustion engine in a piece of metal and mounted that on a board. To create the spark I used a standard ignition coil with a Velleman kit. The Velleman kit (K2543) comes with everything needed, but it has to be assembled. The coil is an auto-transformer that can be bought on Amazon. Auto-transformers are used in cars to generate the spark.

Auto-transformers work by storing a large charge of energy in a coil, then when the energy source is removed, the stored energy is given a path to flow through a gap, such as a spark plug. When this happens it makes a spark. A schematic is below. This particular version isolates the antenna from the circuit with a transformer. The antenna is grounded to earth to complete the circuit on the secondary.

Auto-transformers work by storing a large charge of energy in a coil, then when the energy source is removed, the stored energy is given a path to flow through a gap, such as a spark plug. When this happens it makes a spark. A schematic is below. This particular version isolates the antenna from the circuit with a transformer. The antenna is grounded to earth to complete the circuit on the secondary.

A spark is considered the fourth state of matter. The others are: gas, fluid and solid. (ex. Steam, water and ice) A more scientific name is plasma. Other sources of plasma are vacuum tubes and Nixie tubes. Capacitors can be used in place of auto-transformers. (see picture)

This schematic is over simplified. It has no way to vary the source to create AC. If there was a switch between the source and R when it is thrown C1 would charge through R. The source is then removed, and C1 would discharge through C2 and L by 'jumping' the gap. The antenna between C2 and L would radiate a very interfering signal.

A spark is considered the fourth state of matter. The others are: gas, fluid and solid. (ex. Steam, water and ice) A more scientific name is plasma. Other sources of plasma are vacuum tubes and Nixie tubes. Capacitors can be used in place of auto-transformers. (see picture)

This schematic is over simplified. It has no way to vary the source to create AC. If there was a switch between the source and R when it is thrown C1 would charge through R. The source is then removed, and C1 would discharge through C2 and L by 'jumping' the gap. The antenna between C2 and L would radiate a very interfering signal.

I think it would be possible to 'record' the interference created by a spark generator, make a computer file out of it, then use it in a small hand held personal area network jamming device.

I think it would be possible to 'record' the interference created by a spark generator, make a computer file out of it, then use it in a small hand held personal area network jamming device.

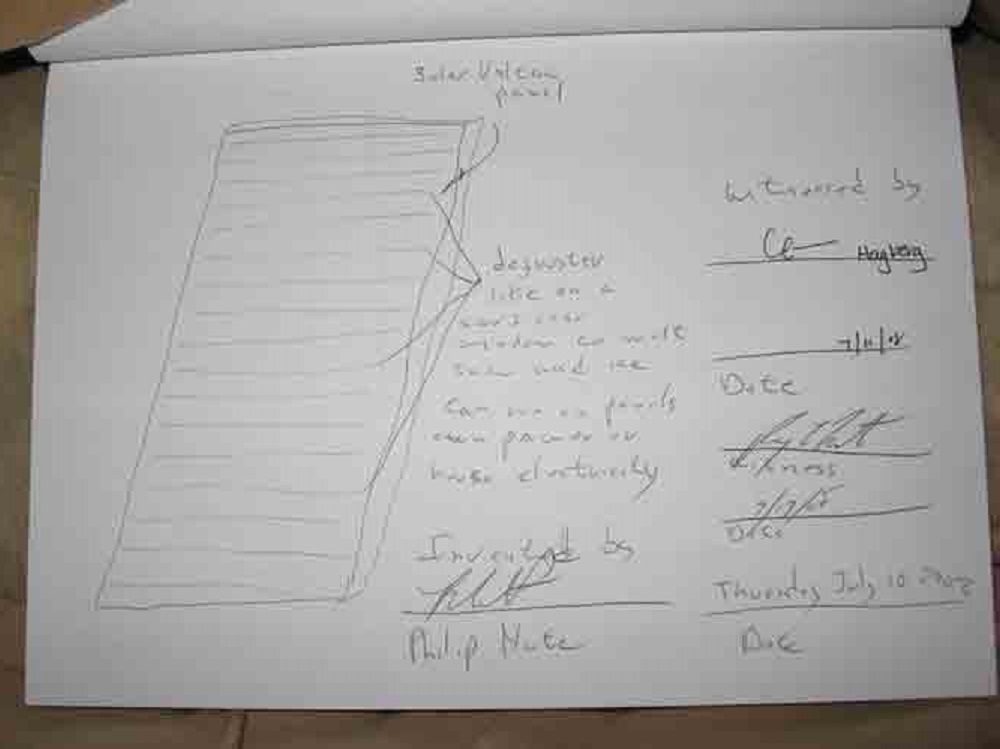

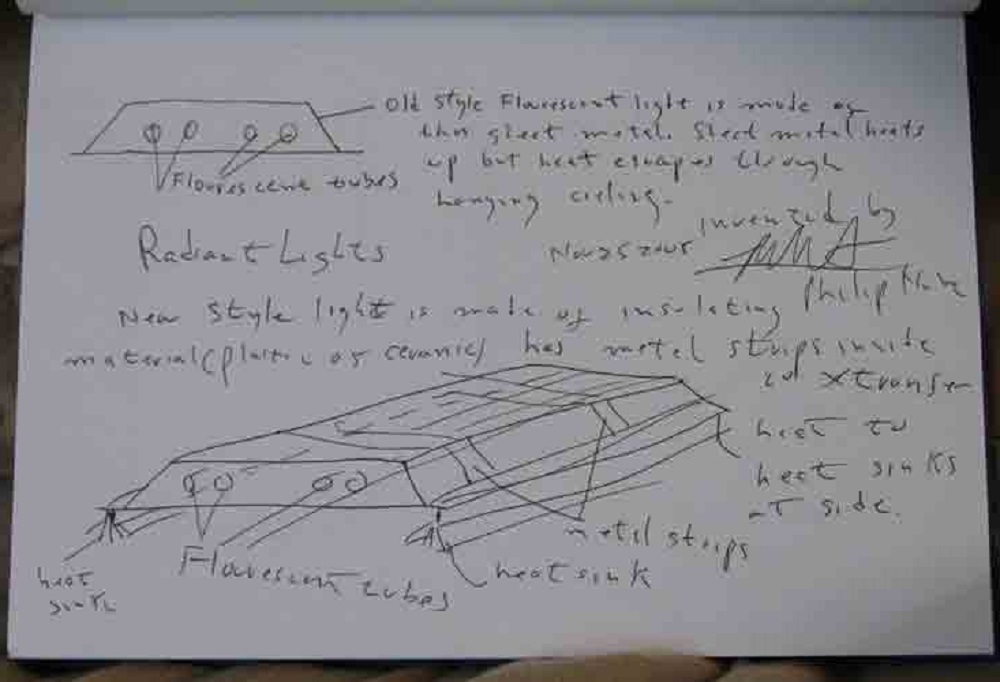

Electric Heat

Solar panels convert sunlight to DC electric current with semiconductor technology. They use the same PN junction used in every transistor. Silicon transistors can make light. It’s called an LED. (Light Emitting Diode) So it can both make electricity from light and make light from electricity. That's about as much as I know.

There are 3 types of solar panels. Amorphous, poly-crystalline and mono-crystalline. Amorphous are the least sensitive and cheapest. Poly-crystalline are in the middle and mono-crystalline are the most sensitive and costly. Amorphous are best used near the equator where there is abundant direct sunlight. They don’t work very well near the poles. (north and south) It is best to use the most sensitive where the sunlight is not as direct.

Any integrated circuit (IC) has millions of transistors with millions of PN junctions. Soon after IC's were invented someone predicted that the number of transistors per square inch would double every 18 months. That was sometime in the 1950's. By the 1970's Intel had made the first microprocessor with millions of transistors. Engineers referred to the progression as Small Scale Integration (SSI) then they went to Large Scale Integration (LSI) Then VLSI and so on. In a world dominated by oil companies I wonder if photo voltaic panels were ever produced with the new technology. It would put the oil companies out of business. I also know that there are different processes for the different types of light. Infrared, ultra violet and visible. Maybe combining today's integration technology and all the various light types if the amount of current produced by photo voltaic panels can be significantly increased.

The manufacturing process for creating IC's is very similar to the process that makes PCB's. (printed circuit boards) It is very chemical dependent and requires a number of steps. I wonder if the technology that makes CD's can be used to create IC's. Every computer sold today comes with a CD burner. It uses a LASER to burn 'holes' in the bottom of a blank CD. The 'hole' is microscopic. I think it's possible to make IC's with LASER's this would eliminate chemicals and make them cheaper.